Ensuring Aviation Safety: The Critical Role of Airfield Obstruction Lights

Airfield obstruction lights are essential safety devices designed to mark hazards such as towers, buildings, cranes, and other structures near airports and flight paths. These lights ensure that pilots can easily identify potential obstacles, particularly during nighttime or low-visibility conditions. As air traffic increases and urban development expands, the importance of reliable airfield obstruction lighting systems becomes even more pronounced.

This article examines the purpose, types, regulations, and technological advancements of airfield obstruction lights, emphasizing their role in preventing accidents and enhancing aviation safety.

Purpose and Function of Airfield Obstruction Lights

The primary function of airfield obstruction lights is to alert pilots to the presence of tall or hazardous structures that could interfere with aircraft operations. These lights are strategically placed on obstacles to ensure maximum visibility from various angles and distances.

Key characteristics of effective airfield obstruction lights include:

High Visibility – Bright, flashing, or steady lights that stand out against both day and night skies.

Durability – Designed to withstand harsh weather conditions, including heavy rain, snow, and strong winds.

Compliance with Aviation Standards – Must meet strict regulatory requirements to ensure uniformity and reliability.

By providing clear visual warnings, these lights help pilots maintain safe distances from obstacles, reducing the risk of collisions.

Types of Airfield Obstruction Lights

Different types of obstruction lights are used depending on the height, location, and risk level of the structure. The most common classifications include:

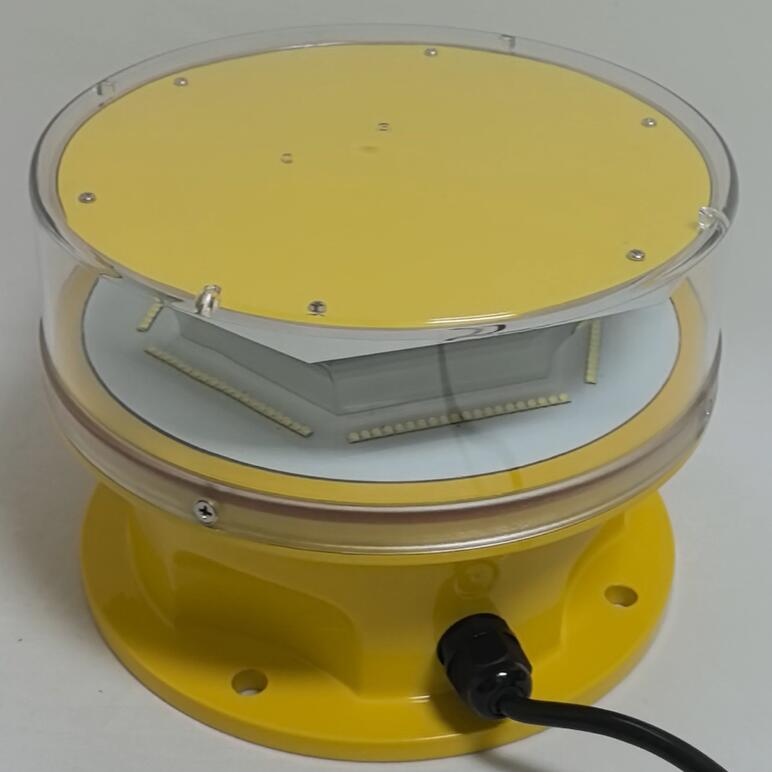

| airfield obstruction lights |

1. Low-Intensity Obstruction Lights (L-810)

Used for structures below 150 feet (45 meters).

Typically emit steady red light.

Common on small buildings, utility poles, and minor obstructions.

2. Medium-Intensity Obstruction Lights (L-864 & L-865)

Installed on structures between 150 and 500 feet (45–152 meters).

Available in Type A (white strobe for daytime) and Type B (red for nighttime).

| airfield obstruction light |

Often seen on communication towers and wind turbines.

3. High-Intensity Obstruction Lights (L-856 & L-857)

Required for structures exceeding 500 feet (152 meters).

Extremely bright white strobes visible for miles.

Used on skyscrapers, tall transmission towers, and near major airports.

4. Dual Lighting Systems

Combine red lights for nighttime and white strobes for daytime.

Ensure 24/7 visibility in all weather conditions.

Mandatory for critical infrastructure near flight paths.

Regulatory Standards for Airfield Obstruction Lights

To maintain global aviation safety, several organizations enforce strict lighting standards:

Federal Aviation Administration (FAA) – Sets guidelines under Advisory Circular 70/7460-1L.

International Civil Aviation Organization (ICAO) – Defines international standards in Annex 14.

European Aviation Safety Agency (EASA) – Regulates obstruction lighting in Europe.

Key requirements include:

Proper light intensity and flash rate.

Correct placement and spacing on structures.

Regular maintenance and failure monitoring.

Compliance ensures that pilots worldwide can rely on consistent visual cues, regardless of location.

Technological Advancements in Airfield Obstruction Lights

Modern obstruction lighting systems have evolved significantly, incorporating new technologies for better performance and efficiency:

1. LED Lighting

More energy-efficient than traditional incandescent or xenon lights.

Longer lifespan, reducing maintenance costs.

Brighter and more reliable illumination.

2. Solar-Powered Systems

Ideal for remote or off-grid locations.

Environmentally friendly with battery backup for continuous operation.

Reduces dependency on electrical infrastructure.

3. Smart Monitoring and Control

IoT-enabled sensors for real-time status monitoring.

Automatic fault detection and alerts for maintenance teams.

Remote brightness adjustment based on visibility conditions.

4. Eco-Friendly Designs

Reduced light pollution with directional lighting.

Compliance with dark sky regulations in environmentally sensitive areas.

Adaptive lighting that dims when not needed.

Challenges and Future Trends

Despite their effectiveness, airfield obstruction lights face several challenges:

Light Pollution – Bright strobes can disrupt wildlife and nearby communities.

Harsh Environmental Conditions – Extreme weather can damage lighting systems.

Maintenance Accessibility – Difficult-to-reach structures require specialized servicing.

Future innovations may include:

AI-Powered Predictive Maintenance – Using machine learning to anticipate failures before they occur.

Enhanced Drone Inspections – UAVs equipped with cameras to inspect and maintain obstruction lights.

Integration with Air Traffic Systems – Real-time data sharing for improved situational awareness.

Airfield obstruction lights play a vital role in aviation safety by clearly marking hazards and preventing collisions. With advancements in LED technology, solar power, and smart monitoring, these systems are becoming more efficient and sustainable. As air traffic grows and urban structures rise higher, the demand for reliable obstruction lighting will only increase.

By adhering to international regulations and embracing new technologies, the aviation industry can ensure that airfield obstruction lights continue to protect pilots, passengers, and infrastructure for years to come. Their evolution will remain a key factor in maintaining safe skies worldwide.